Tapered plugs are used to repair and stop leaks in condensers, chillers and heat exchangers. They are driven into tube ends with a soft faced hammer until seated and sealed tight eliminating future leaks. Welding is optional depending on your application. Select a plug where the middle diameter will approximately match your tubing ID. It is best not to drive the plug in flush when installing, but to leave 1/4″ of the length exposed. The photo reveals grooved finishes for a better gripping surface, but smooth plugs are available as well. A wide range of sizes are manufactured from 2” down to .25”. Materials shown in the photo are 360 brass, 316L stainless steel and titanium; however, we will manufacture to your specifications and provide material certifications to suit your application. We understand that quick deliveries are critical for field maintenance and we won’t let you down. Please contact us for all your tapered plug needs.

Author: Bill Wilke

Category Archives: Restore Worn Machine

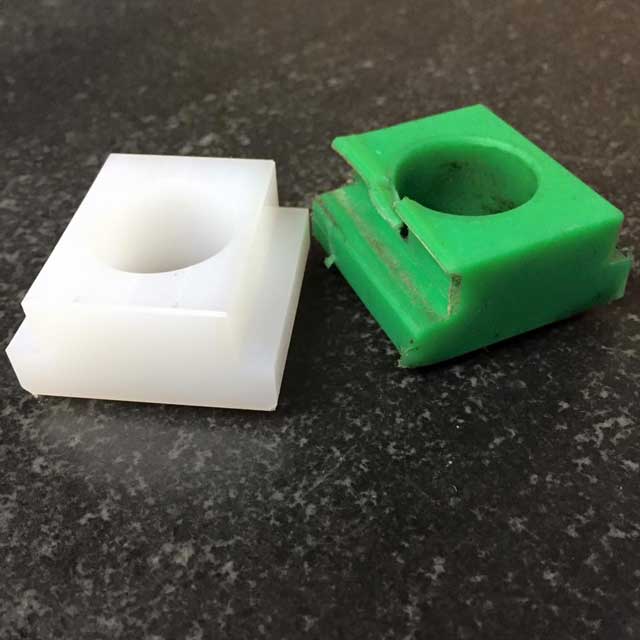

Machined White UHMW Plastic

New machined white UHMW plastic T-nut compared to a worn green reprocessed part.

If your machine or equipment is wearing out, don’t replace the whole machine with an expensive new one. Have MLP reverse engineer and machine a replacement part(s) and keep that equipment running.

Machined White UHMW Plastic

Case Study:Production Line Halts, OEM item obsolete, MLP’s Reverse Engineering

Case Study:Production Line Halts, OEM item obsolete, MLP’s Solution: Reverse Engineering

Case Study:Production Line Halts. An International medical supplies manufacturer is threatened with a production line coming to a halt. The manufacturer wants to avoid the production line slowing or worse, shutting down completely, and choking off production of their much needed products.

Reason: The OEM supplier of a critical component declares the item obsolete.

Solution: MLP will use Reverse Engineering of the worn obsolete OEM component using mating parts.

Here’s how the process works at Mid’lantic Precision Inc. “aka” MLP.

1. MLP receives the worn obsolete OEM item and mating components and in conjunction with the customer discusses the application as well as the shortcomings of the current design.

2. MLP creates the new CAD file with improved design features to enhance the value for the customer.

3. MLP manufactures the stainless steel item and maintains the CAD file and finished items in our inventory.

The value to the customer: They maintain and extend the useful life of the current processing line as well as increase durability and availability of critical components.

Let MLP help keep your production line from coming to a halt because the OEM says your production line is obsolete. Contact us to get started reverse engineering that much needed part to keep you company producing products. Click here to contact us at MLP.